LEWIS Metal Deck

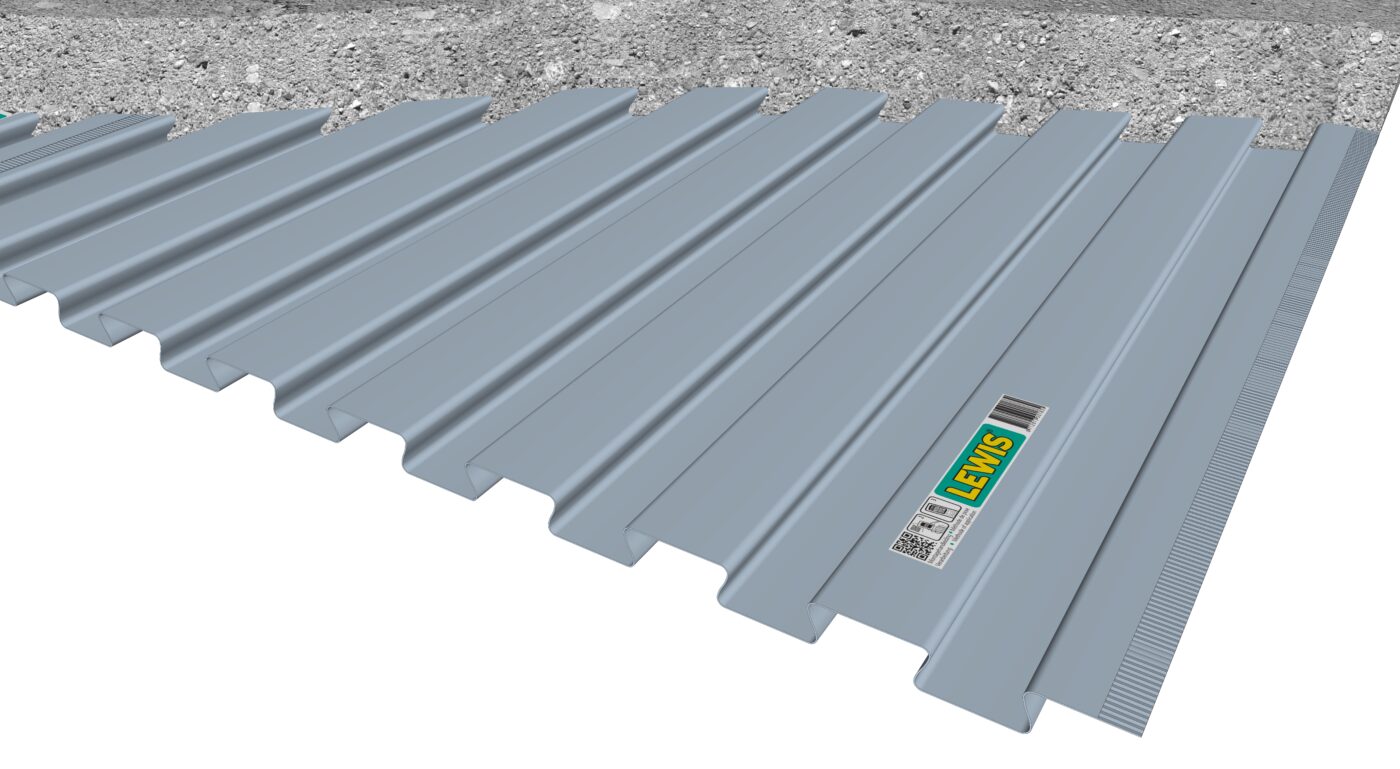

LEWIS Metal Deck are the original rolled dovetailed steel sheets

Solutions for your project

Thanks to years of experience and close customer relationships, Reppel’s specialists know exactly how to optimally support the customer in every part of the construction process.

LEWIS Metal Deck are the original rolled dovetailed steel sheets. Ideal for shuttering and reinforcing thin lightweight concrete floors on wooden, steel or other bearing constructions.

LEWIS metal deck provides a first class solution for ACOUSTICS, FIRE PROTECTION and works well with UNDERFLOOR HEATING AND COOLING systems.

LEWIS metal decking solutions can be used in a varied range of projects from renovation and conversions to traditional new build, timber frame, off-site system building, modular building systems and mezzanine floors.